PTFE Coated Fiberglass uses high-quality electronic grade glass fiber cloth as the base cloth. It is an excellent high temperature resistant material combined with polytetrafluoroethylene (PTFE) emulsion through precise impregnation and coating processes.. Through our years of unremitting efforts, we have been able to optimize the thickness of fiberglass cloth to an ultra-thin level of 0.04mm while ensuring its strength. It has been widely used in various fields due to its excellent performance.

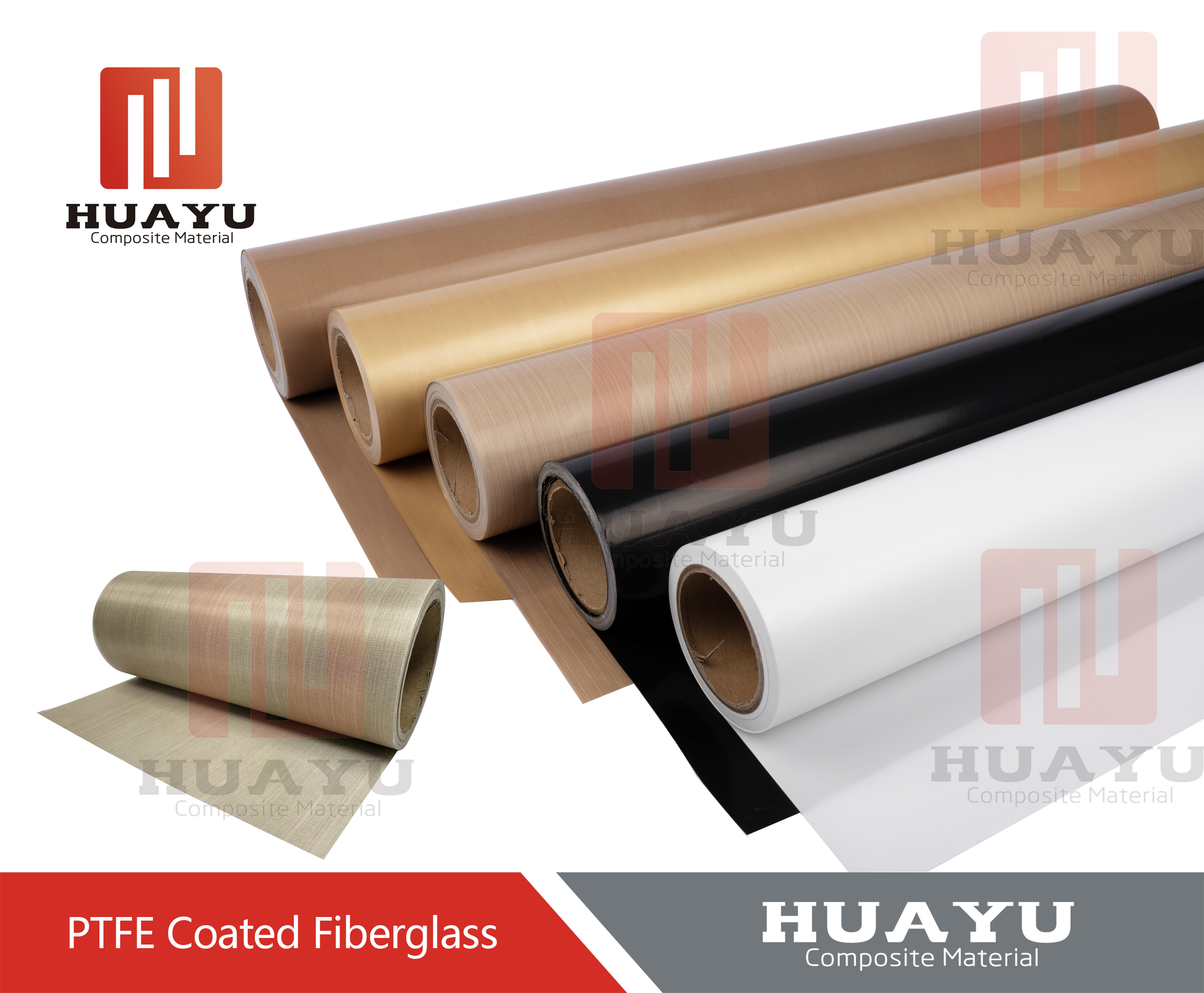

It comes in a variety of colors, including brown, black, white, blue and gold, with thickness ranging from 0.04 mm to 1.0 mm, and the main texture is plain.

PTFE Coated Fiberglass is popular for its unique characteristics. First of all, it has excellent temperature resistance and can be used between -196℃ and 360℃, showing extraordinary climate adaptability and anti-aging capabilities. Secondly, its non-adhesive nature makes it difficult for any substance to stick to it, making it a breeze to clean, whether it is oil stains, stains or other attachments, it can be easily removed.

In addition, it also has excellent chemical stability and can resist corrosion from strong acids, strong alkali, aqua regia and various organic solvents. Its friction coefficient is low, only 0.05-0.1, making it an ideal choice for oil-free self-lubrication. High insulation performance, anti-ultraviolet, anti-static and other characteristics make it widely used in the electrical field.

It has good dimensional stability, an elongation coefficient of less than 5‰, and high strength, giving it good mechanical properties. Its resistance to chemicals and non-toxicity allows it to be used in a variety of environments and usage scenarios. More importantly, PTFE Coated Fiberglass has fire-retardant properties, providing a strong guarantee for safe use.

In terms of application fields, PTFE Coated Fiberglass has shown wide applicability. It can be used as anti-adhesive linings, gaskets, covers and conveyor belts, and can be used in conveyor belts of various drying machinery, adhesive tapes, sealing tapes, etc. At the same time, it is also an ideal choice for welding and sealing of plastic products, as well as an ideal material for electrical insulation. It also plays an irreplaceable role in anti-corrosion coating of petrochemical pipelines and environmentally friendly desulfurization of power plant waste gas.

In addition, it can also be used in microwave gaskets, oven sheets, food drying and other fields, as well as in various application scenarios such as adhesive tapes, transfer printing ironing table cloths, and carpet adhesive cured conveyor belts. After special processing, it can even be made into "anti-static cloth" to meet more stringent usage requirements.

Specifications of PTFE Coated Fiberglass :

Item No | Color | Thickness | Max width | weight | Tensile strength | Temperature |

HY-F004Z | brown | 0.04 | 1250mm | 56 g/m² | 90/120N/cm | -140 to 360℃ |

HY-F005Z | brown | 0.05 | 1250mm | 78 g/m² | 100/120N/cm | -140 to 360℃ |

HY-F008Z | brown | 0.08mm | 1250mm | 165g/m² | 130/120N/cm | -140 to 360℃ |

HY-F008H | black | 0.08mm | 1250mm | 170 g/m² | 130/120N/cm | -140 to 360℃ |

HY-F008H | black | 0.08mm | 1250mm | 185 g/m² | 130/120N/cm | -140 to 360℃ |

HY-F013Z | brown | 0.13mm | 1250mm | 260 g/m² | 220/190N/cm | -140 to 360℃ |

HY-F013H | black | 0.13mm | 1250mm | 275 g/m² | 220/190N/cm | -140 to 360℃ |

HY-F013B | white | 0.13mm | 1250mm | 275 g/m² | 220/190N/cm | -140 to 360℃ |

HY-F018Z | brown | 0.18mm | 1250mm | 395 g/m² | 330/250N/cm | -140 to 360℃ |

HY-F018HF | black | 0.18mm | 1250mm | 415 g/m² | 330/250N/cm | -140 to 360℃ |

HY-F025Z | brown | 0.25mm | 2800mm | 490 g/m² | 410/330N/cm | -140 to 360℃ |

HY-F025HF | black | 0.25mm | 2800mm | 510 g/m² | 410/330N/cm | -140 to 360℃ |

HY-F035Z | brown | 0.35mm | 3200mm | <660 g/m² | 560/445N/cm | -140 to 360℃ |

HY-F035HF | black | 0.35mm | 3200mm | 680 g/m² | 560/445N/cm | -140 to 360℃ |

HY-F040Z | brown | 0.40mm | 3500mm | 780 g/m² | 820/500N/cm | -140 to 360℃ |

HY-F040HF | black | 0.40mm | 3500mm | 820 g/m² | 820/500N/cm | -140 to 360℃ |

HY-F065Z | brown | 0.65mm | 4000mm | 1150 g/m² | 1080/750N/cm | -140 to 360℃ |

HY-F090Z | brown | 0.90mm | 4000mm | 1550 g/m² | 1500/1250N/cm | -140 to 360℃ |

HY-F090H | black | 0.90mm | 4000mm | 1650 g/m² | 1500/1250N/cm | -140 to 360℃ |

According to different application scenarios, we carefully create a variety of PTFE Coated Fiberglass grades to meet various needs.

1. Ordinary industrial-grade products are widely used in various industrial fields due to their excellent heat resistance, anti-corrosion and non-stick properties.

2. Standard-grade products are made of imported high-quality materials. They not only have excellent anti-corrosion and heat-resistant properties, but also have a smooth and flawless surface like a mirror. They also show outstanding advantages in the fields of plastic demoulding, product separation, gaskets and demoulding surfaces.

3. Food grade product, its smooth and flat surface, excellent anti-stick and heat resistance properties, and easy cleaning ensure safe application in the food industry.

4. Anti-static grade products, the electronic anti-static coefficient is uniform and stable, and is favored by industries such as electronics, plastics, textiles and printing.