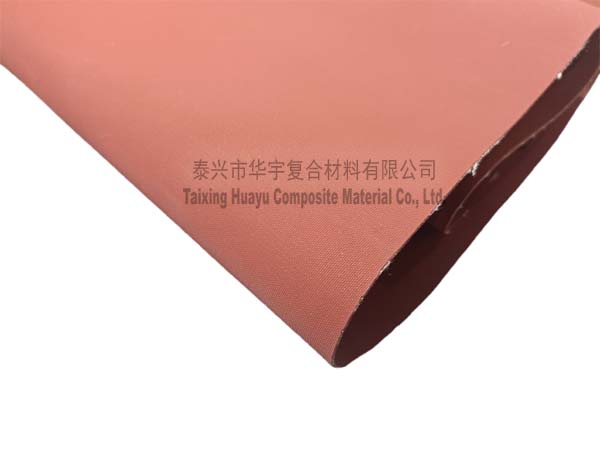

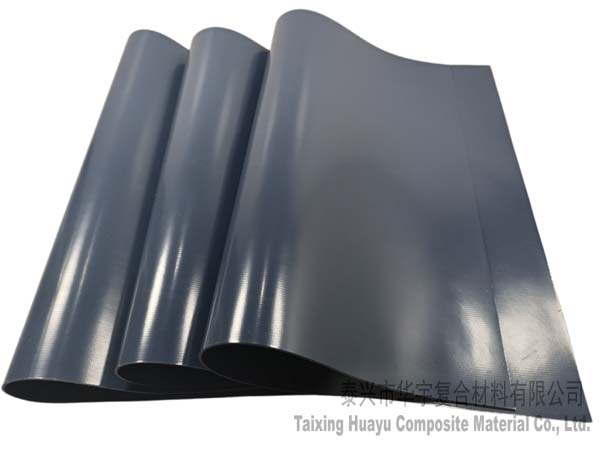

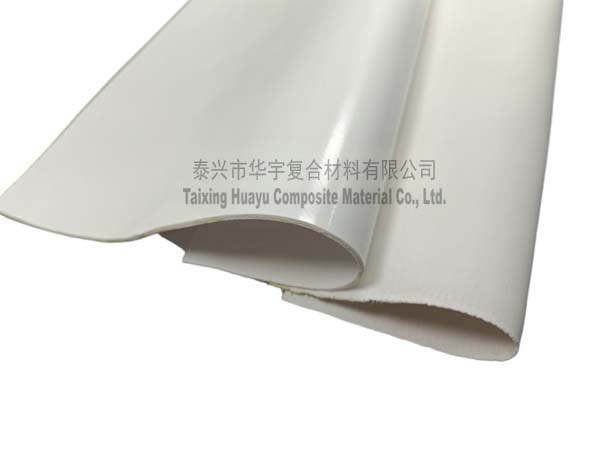

Silicone coated Aramid fabric, also called Silicone Calendered Kevlar fabric, is a flexible composite material made from a Kevlar fabric base fabric, coated and vulcanized with a layer of silicone rubber on one or both sides through a calendering process.

Its structure is shown as the bellowing:

A high-temperature-resistant silicone layer (on one or both sides) + a high-strength Kevlar fabric reinforcement layer.

"Calendering" is a key process, involving a series of precisely controlled rollers that press the silicone rubber mixture into the gaps in the Kevlar fabric, forming a strong, uniform adhesive layer with a strong bond to the base fabric.

Silicone coated Aramid fabric can be classified according to various criteria:

1. By coating surface:

· Single-sided silicone fabric: Silicone rubber is applied only to one side of the Kevlar fabric. Suitable for applications requiring insulation protection on one side while retaining the fabric's properties on the other.

· Double-sided silicone fabric: Silicone rubber is applied to both sides of the Kevlar fabric. This is the most common type, providing comprehensive sealing, protection, and insulation.

2. Classification by Silicone Rubber Properties:

· Ordinary Silicone Rubber Coating: Offers excellent heat resistance and elasticity.

· Flame-Retardant Silicone Rubber Coating: Flame retardants are added to ordinary silicone rubber, giving it extremely high flame retardancy and even fire resistance (meets standards such as UL94 V-0).

· Conductive Silicone Rubber Coating: Conductive fillers (such as carbon black or metal particles) are added to impart electromagnetic shielding (EMI/RFI) or antistatic properties.

3. Classification by Kevlar Fabric Type:

· Kevlar fabrics can be made in various weights, weaves (such as plain or satin), and yarn densities, which affect the thickness, flexibility, and strength of the final product.

4. Classification by Function:

· Fire and Heat Insulation Fabric: Provides high-temperature protection and flame retardancy.

· Abrasion-Resistant Protective Fabric: Provides high abrasion and tear resistance.

· Electrical Insulation Fabric: Provides high insulation ratings.

Silicone coated Aramid fabric perfectly combines the advantages of Kevlar fiber and silicone rubber:

Features of the Kevlar / Aramid Fabric :

· Extremely high mechanical strength: Excellent tensile strength, tear resistance, and puncture resistance. Its specific strength is over five times that of steel wire of equal weight.

· Excellent heat resistance: It will not melt at high temperatures and is self-extinguishing.

· Excellent dimensional stability: It will not stretch or deform under high temperatures and tension.

· Inherently flame retardant: Kevlar is a flame retardant material.

Features of the silicone rubber coating:

· Wide temperature resistance: Silicone rubber typically maintains its elasticity over long periods of time in environments ranging from -60°C to 250°C (up to 300°C for short periods) without becoming brittle or melting.

· Excellent weather resistance: It is resistant to ozone, UV rays, and aging, ensuring a long service life. · Good chemical inertness: It offers excellent resistance to water, ozone, alcohol, weak acids and bases.

· Soft and flexible: It maintains excellent flexibility and elasticity, making it easy to install and form.

· Electrical insulation: Silicone rubber is an excellent insulating material.

The synergistic effect of the two:

· Excellent all-round protection: It overcomes the shortcomings of pure Kevlar cloth (its inability to withstand sustained high temperatures and UV rays, which requires coating protection) while also making up for the mechanical strength shortcomings of pure silicone film.

· Safe, environmentally friendly, and non-corrosive: Unlike some coating materials, silicone rubber is non-corrosive to most metals.

Due to its comprehensive properties, Silicone coated Aramid fabric is widely used in applications requiring extremely high safety, strength, and heat resistance:

1. High-temperature protection (primary application):

· Welding protection: It is used in welder's curtains, shields, and welding blankets to prevent sparks and slag from igniting or damaging surrounding equipment and objects. · Fireproofing and Thermal Insulation: Used for thermal insulation coatings on pipes and equipment, flexible connectors and expansion joints for high-temperature furnaces and thermal equipment, and protective gear for firefighters.

· Aerospace: Used for fireproof jacketing of wiring harnesses, oil pipes, and other components in aircraft engine areas to isolate heat sources.

2. Industrial Protection:

· Wear Protection: Used as guide plates, chute linings, and conveyor belts in conveying systems (especially those transporting sharp and high-temperature materials), providing exceptional wear and tear resistance.

· Equipment Protection: Used as coverings on precision equipment or workbenches to prevent damage from collisions or sparks to tools and parts.

3. Electrical Insulation:

· High-Temperature Insulation: Used for insulation and thermal protection of motors, transformers, and cables (especially fire-resistant cables) in high-temperature environments.

· Flexible Connectors: Used for electrical components requiring flexible connections and insulation.

4. Safety and Emergency:

· Rescue and Escape: Used in the manufacture of high-temperature rescue blankets, escape slides, and more. Motorsports: Used as fire barriers in racing car engine compartments to protect drivers.

5. Other Specialty Applications:

• Used as flexible protective covers for robots requiring high strength, heat resistance, and insulation.

• Used as a material for special clothing or gloves that are cut-resistant and heat-resistant.